-

Bigger, Stronger, Lighter™

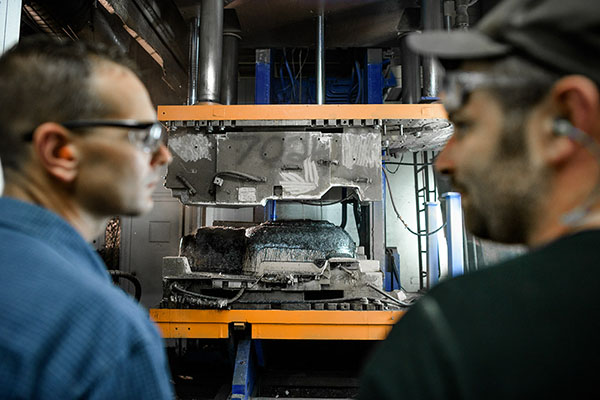

Our Reaction Injection Molding Processes

Dicyclopentadiene (DCPD)

Long Fiber Injection

Polyurethane Elastomers

In-Mold Paint

Why Choose Romeo RIM?

We are built solely to be your full service supplier by providing design and engineering support, rapid prototyping, lean product development for your reaction injection molding projects.

You know that feeling of pride and excitement you get when your idea is brought to life and you see it in the market?

We exist to help you capture that feeling. 😊

By providing Bigger, Stronger, Lighter Reaction Injection Molded parts, we believe in serving those with the ideas that will make a difference in their world.

What to Expect

PARTNER

CREATE

COLLABORATE

DEPLOY

Frequently Asked Questions

-

What markets do you serve?Romeo RIM has typically produced large parts for industries like Agriculture, Construction, Transportation, Heavy Truck, UTV’s and Spas. But we are not limited to those markets. If you need parts that are bigger, stronger or lighter, we can likely produce it. Give us a call. 586-336-5800

-

What is Long Fiber Injection?Long fiber injection is a process in which polyurethane resin and chopped fiberglass are poured into an open mold. Low compression pressure is then used to create complex parts with B-side features and Class A surface finishes in a variety of sizes. Long Fiber Injection parts are used in applications where weight and stiffness are important like: Roofs, Doors and other applications to replace heavier materials but retaining strength.

-

What is Dicyclopentadiene?Dicyclopentadiene, aka DCPD or C10H12, is an artificial chemical compound used in a closed mold process. DCPD resin is characterized by its low viscosity and its resistance to heat, impact, and corrosive chemicals. Parts made of DCPD allows them to be large, strong, and lightweight and are thus used in applications like: protective coverings, shields, hoods as well as the outer bodies of cars, trucks and machinery.

-

What are Polyurethane Elastomers?Polyurethane Elastomers are processed via closed mold where polyurethane is injected into the mold along with a blowing agent to achieve various properties. Polyurethane elastomers are extremely resilient and impact resistant and can be used in many applications like: bumpers, fenders, side cladding and more…

-

Do you make Wheel Rims?No. We, in fact, do not make wheel rims. 🙂 We get that a lot.

Testimonials

Tremendous Job!

Exceeds Expectations!

Impressed With Quality!

Significantly Better Than Competition

We value Relationships & Accomplishments

Got a Project?

We do this by bringing together a deep understanding of our customer’s needs, then match it with the right material, process, and part design.

Cradle to Grave Product Management

Logistics Support

Rapid Prototyping

Certified Program Management

Lean Product Development

Research & Development